pvd PROCESS

Electron Beam Evaporation

EBPVD

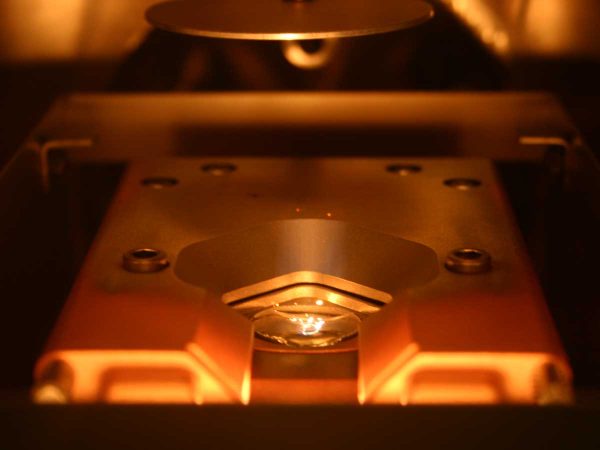

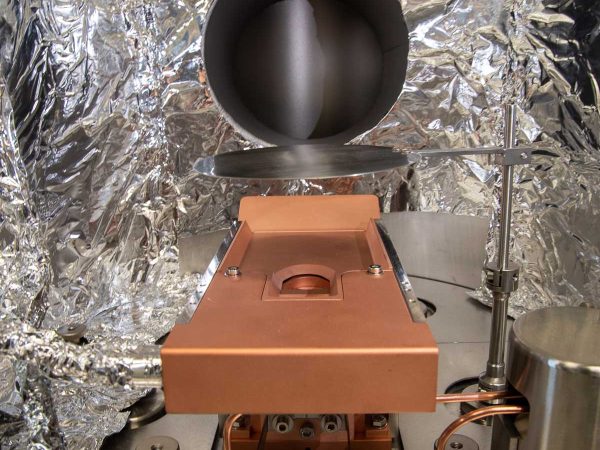

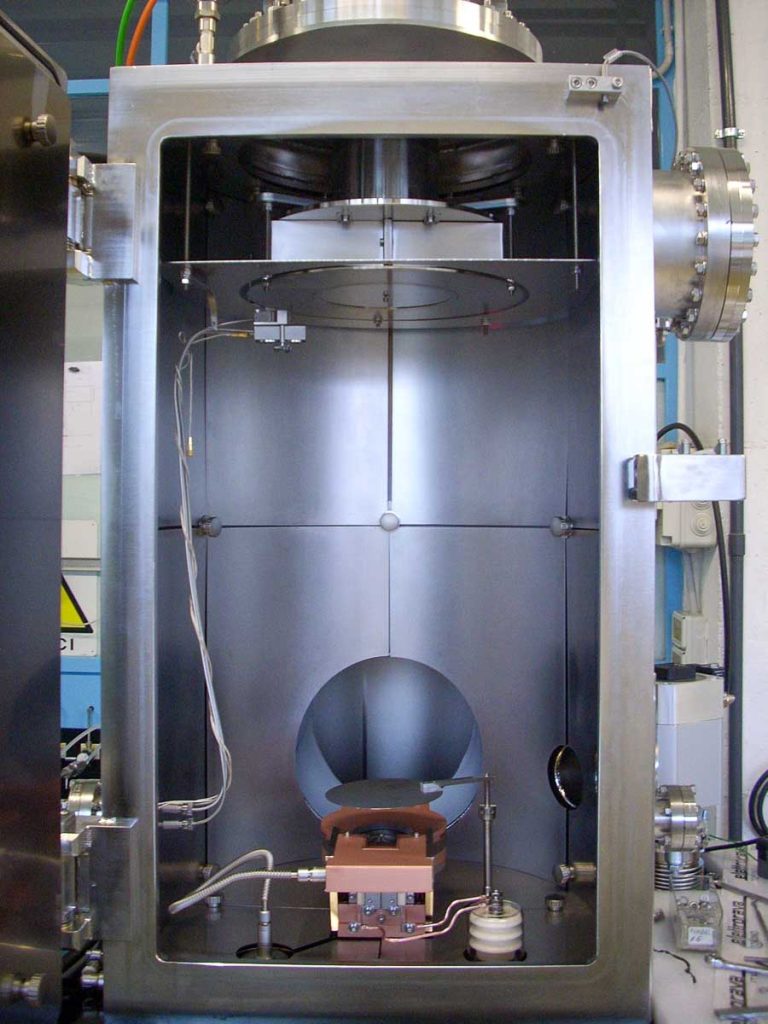

Electron Beam Evaporation (EBPVD) is a physical deposition technique used to create thin films on a substrate surface by evaporating a solid material placed in a crucible. The e-beam is generated through the thermionic emission process, where an electric current passes through a tungsten filament, causing the filament to heat up and emit electrons. High voltage is then applied between the filament and the hearth, allowing the liberated electrons to accelerate towards the crucible, while a magnetic field focuses them into a beam. The collimated electron beam hits the material in the crucible, allowing the evaporation process and the aggregation on the substrate surface. Compared to thermal PVD, EBPVD allows high evaporation temperature materials deposition as thin films. Deposition rates using electron beam processes can vary from 1 nm per minute to several μm per minute, depending on the required structural and morphological film control.

Applications

E-beam evaporation finds widespread use in various industries, like semiconductor, thin-film solar, aerospace, and cutting and tool industries, for producing wear-resistant and thermal barrier coatings. This technique is used also to produce dielectric, optical coatings, and Josephson junctions and in micro and nano-fabrication for lift-off processes.

- Automotive Industry

- Consumer Electronics

- Aerospace and Defence

- Healthcare and medical devices

- Optics and Photonics

- Energy storage

Key features

- OHFC copper hearth crucible with up to 8 pockets of various sizes

- HV or UHV configuration

- Fully integrated quartz crystal controller for the automatic control of the thickness

- Optional reactive gases, such as oxygen or nitrogen useful to reactively deposit non-metallic films

- Optional automatic or manual load lock with optional pre-heating and/or plasma treatments

- Optional ion beam source for bombarding the substrates during deposition (Ion Beam Assisted Deposition - IBAD)

- Evaporation sources come in various sizes and configurations, single or multiple pockets

Deposited materials

Metals, Oxides, Nitrides, Carbides, Semiconductors

Similar technologies

Electron Beam Evaporation

the right choice for high deposition rates and high quality metal and dielectric films